Rebuilt: .eco champion

Buildings account for a big chunk of our global carbon footprint. Many of those emissions are from manufacturing building materials. Rebuilt is guiding the industry to build with lower carbon materials.

Esther Bailey, COO at Rebuilt, answered our questions about how they help reduce the carbon footprint of new buildings.

How do buildings contribute to global climate change?

In two ways: through operational emissions and through the emissions embedded in the materials used to construct them. Operational emissions come from energy used for heating, cooling, lighting, and running equipment over the life of a building. These emissions are well understood and increasingly regulated.

Less visible, but equally significant, are upfront emissions from building materials. These include emissions released during the extraction of raw materials, manufacturing, and transport of products such as concrete, steel, aluminium, and glass. For many new buildings, these emissions are locked in before the building is even occupied and cannot be recovered or offset later through efficiency upgrades.

Globally, the building and construction sector accounts for a large share of emissions, with materials representing a major portion of that total. As operational energy grids decarbonise, the relative impact of material emissions continues to grow. This makes material choice one of the most important levers available to architects, builders, and manufacturers today.

Addressing climate impact in buildings requires a shift from focusing only on energy performance to also understanding, measuring, and reducing the carbon footprint of the products that go into every project.

What are some challenges to constructing buildings with a low carbon footprint?

There are four main barriers to reducing the carbon footprint of new buildings:

- Lack of data: One of the biggest challenges is access to reliable, comparable data at the product level. Many teams want to reduce carbon but struggle to understand which materials have the biggest impact or how alternatives compare. Without trusted data, decisions often default to cost, availability, or habit.

- Timing: Material decisions are frequently made early, when carbon data is least visible and hardest to access. By the time carbon is measured at a project level, the opportunity to change high impact materials has often passed.

- Perceived cost: Lower carbon options are sometimes assumed to be more expensive, even when this is not always the case. Without clear evidence, it can be difficult to justify change within tight budgets and procurement frameworks.

- Complexity: Carbon reporting standards, terminology, and tools can feel overwhelming, particularly for small teams or manufacturers without dedicated sustainability resources. When the process feels slow or expensive, progress stalls.

Overcoming these challenges requires simpler tools, credible data, and workflows that support better decisions without adding friction to already complex projects.

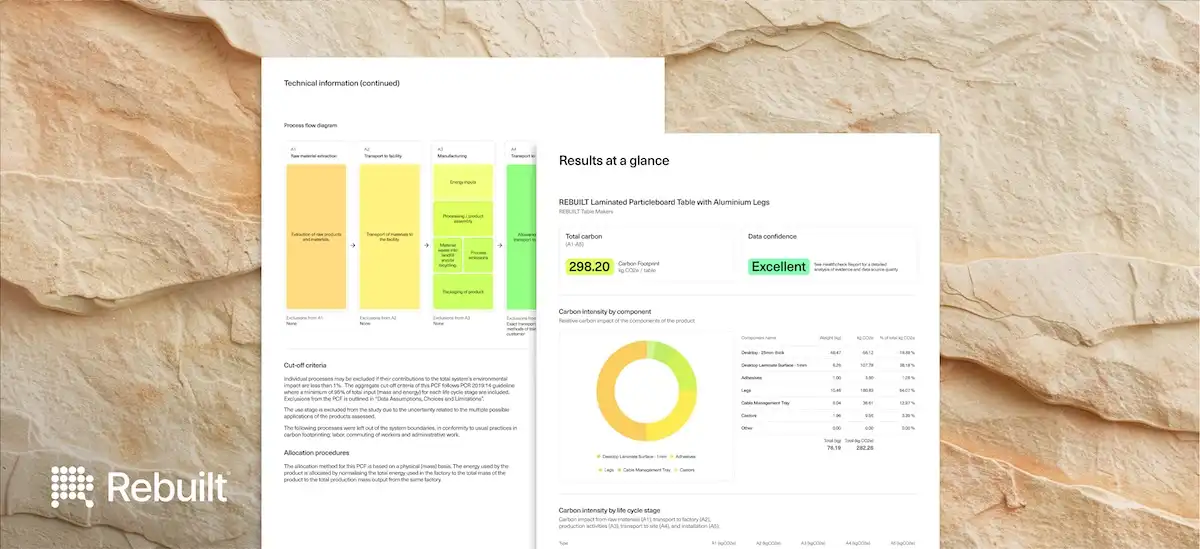

What is a product carbon footprint?

A product carbon footprint, often called a PCF, measures the greenhouse gas emissions associated with making a specific product. In the building sector, this typically focuses on emissions from raw material extraction, manufacturing, and processing, often referred to as cradle to gate.

The result is a single, verified carbon value that shows how much carbon dioxide equivalent is emitted per unit of product, such as per tonne, square metre, or linear metre. This makes it easier to compare products on a like for like basis and understand where emissions are coming from.

Unlike broader environmental declarations, a PCF focuses only on carbon. This makes it faster to produce, easier to understand, and more practical for use in procurement, specification, and reporting.

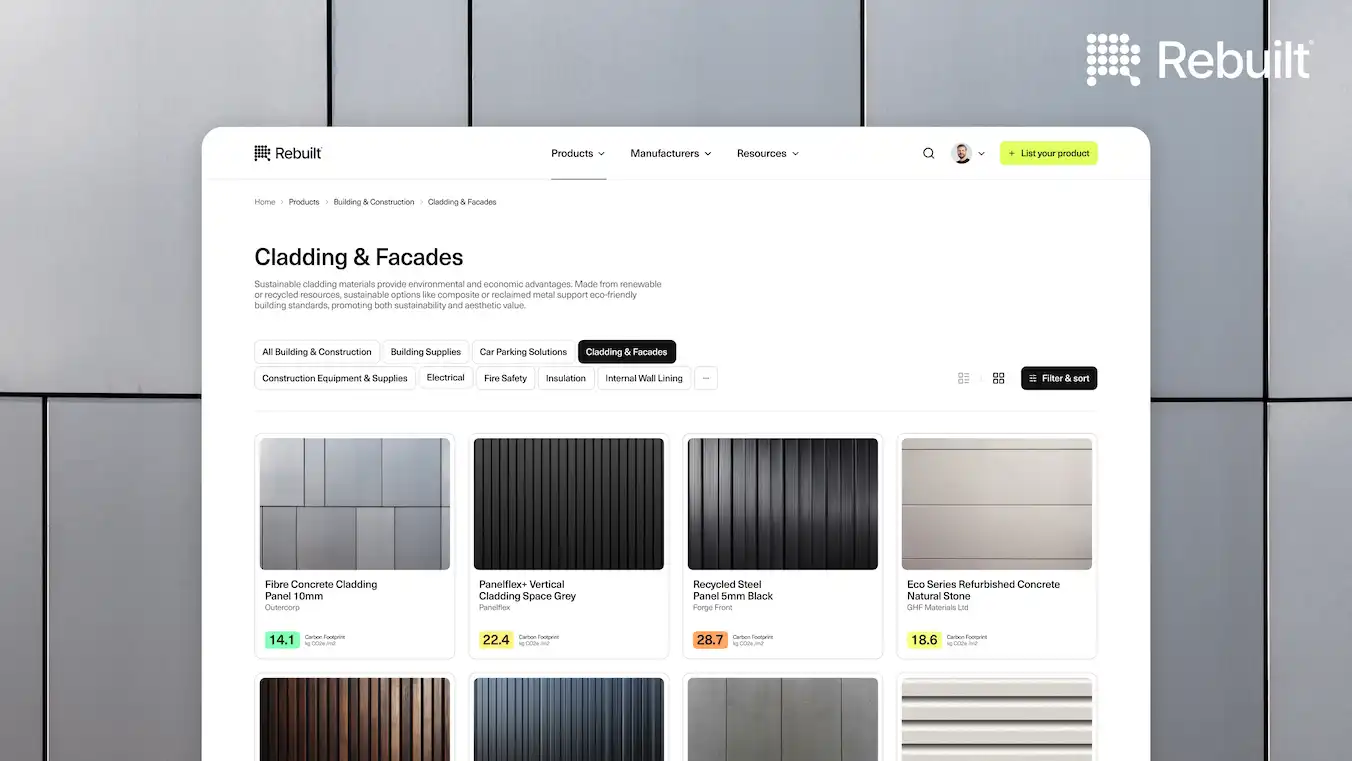

How does Rebuilt help manufacturers of building materials?

Rebuilt helps manufacturers turn carbon data from a compliance burden into a practical business asset. We make it easier to calculate and verify product carbon footprints using processes aligned with international standards, without the time and cost typically associated with traditional reporting.

Beyond reporting, Rebuilt helps manufacturers get discovered. By listing products on the Rebuilt marketplace, suppliers can connect with architects, builders, and procurement teams who are actively looking for credible carbon data. This supports specification and positions manufacturers as prepared partners in low carbon supply chains.

What type of materials have the biggest carbon footprint?

The materials with the largest carbon footprint are typically those used in high volumes and produced through energy intensive processes. Concrete and cement are among the biggest contributors, largely due to the chemical reactions and high temperatures required during cement production.

Steel and aluminium also carry significant carbon impacts. Both rely on energy intensive manufacturing and, in many cases, fossil fuel based processes. These materials are widely used in structural systems, façades, and fitouts, which amplifies their overall impact.

While these structural materials dominate at a project scale, many smaller products collectively add up. Finishes, joinery, insulation, flooring, and fitout components may seem minor individually, but together they represent a substantial share of upfront emissions across a building portfolio.

How are you and fellow .eco community member GECA working together?

Rebuilt and GECA share a common goal of improving transparency, trust, and consistency in sustainability data across the building materials market. Both organisations support better decision-making by providing independently grounded information that helps buyers understand the environmental impact of products.

GECA brings long-established expertise in environmental and social certification, assessing products across a broad range of responsible production criteria. Rebuilt complements this by focusing on verified, product-level carbon data, enabling suppliers to measure and communicate emissions with clarity.

Today, the relationship operates through collaboration and referral within the .eco community, helping businesses access complementary certification and carbon measurement pathways depending on their needs and level of maturity. This alignment supports participation in industry frameworks such as Green Star (Australia) and Infrastructure Sustainability (ISC), where GECA certification can contribute up to 16 Responsible Product Value (RPV) points, with verified product carbon footprints supporting an additional 2 points, subject to project requirements.

By improving access to credible carbon data alongside established certification, the collaboration strengthens GECA’s value proposition for businesses pursuing net-zero and circular economy goals, while supporting Rebuilt’s customers to tender more competitively for Green Star-rated projects. As expectations continue to evolve, both organisations are exploring closer alignment to further reduce complexity and improve access to trusted data across the supply chain.

How did you end up with a .eco domain for your website?

The decision to use a .eco domain was intentional. The .eco top level domain is reserved for organisations that can demonstrate a genuine commitment to environmental responsibility and transparency. It is not available for general registration, which makes it a meaningful signal rather than a marketing label.

For Rebuilt, this alignment matters. Using a .eco domain reflects our purpose and reinforces our emphasis on credibility and accountability.

Being part of the .eco community also connects Rebuilt with other organisations working on practical solutions to environmental challenges. It creates shared expectations around behaviour, evidence, and integrity.

At .eco, we are fortunate to be surrounded by a community of businesses, organizations and individuals working hard to protect our planet. We are honoured to spread the word about the great work they're doing. If you are a member of the .eco community and would like to be featured, get in touch.